ESURGING Maglev Turbo Blower Facilitates development of Fermentation Industry

Human beings have been using yeast for thousands of years; the Egyptians who built the pyramid more than 4000 years ago used fermented bread to be the staple food; ancient Chinese used yeast to brew wine. Till now, yeast is still the necessary material in the food industry; as yeast research progressed, the value of yeast in food, bioengineering, and genetic engineering has been fully played.

The fermentation process is extremely complex since we have to not only add all kinds of raw materials as needed at different times but also monitor and adjust the product indexes in the fermentation tanks to meet the requirements of quality. Therefore, blowers used in the fermentation process must be equipped with adjustment ability to match the technique requirements.

Take Angel Yeast as an example

Angel Yeast, being the first in Asia and the third largest in the world, is the national key high-tech enterprise specialized in the manufacture and sale of yeast, yeast derivatives, and related biological products, owing 10 yeast production bases all over the world in which 2 bases are foreign plants. With a production capacity of more than 260 thousand tons, Angel Yeast is the only A share listed enterprise in the yeast industry in China. Through technique optimization and key manufacturing equipment upgrade, Angel Yeast continues to reduce energy consumption during the fermentation process to practice the development idea of clean production and energy conservation.

In Nov. 2016, to address fermentation blower problems of high energy consumption, low reliability and production capability, through repeated technical advancement demonstration, on-site investigation, and project investigation, Angel Yeast decided to apply domestic maglev blowers to replace old ones and to test its feasibility of implementation in Angel.

Through operating test in 3 months, it is proved that ESURGING maglev blower operates stably, and can save more than 40% of energy than roots blower, more than 25% than foreign screw blower; it has significant energy conservation performance.

Through operating test in 3 months, it is proved that ESURGING maglev blower operates stably, and can save more than 40% of energy than roots blower, more than 25% than foreign screw blower; it has significant energy conservation performance.

A long time before the cooperation with ESURGING, the Angel Yeast fermentation process can only rely on maglev blowers imported from Germany. After the operating investigation, ESURGING maglev blower has obvious advantages in reliability and noise, saving 2% of energy than the imported one--saving about 80kW·h per day!

Reconstruct impeller to increase production capability

How to improve economic benefit based on the current production lines is not only a difficult problem but also a key task that engineers should focus on. ESURGING with engineers of Angel Yeast, through detailed technical analysis of all equipment in the production lines, combining lots of experimental data, believed that it is feasible to raise the fermentation level and adjust technical parameters on the current basis.

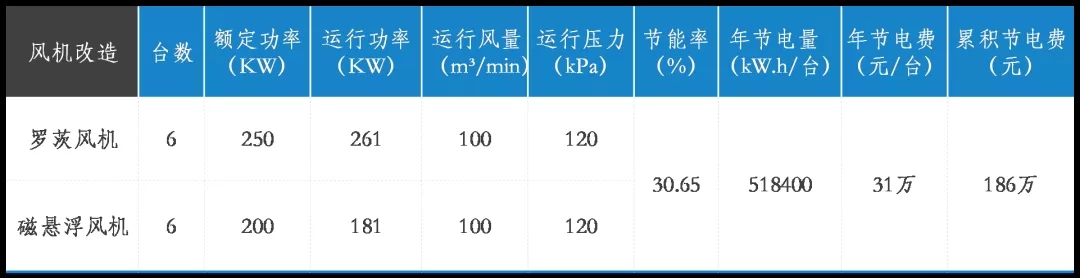

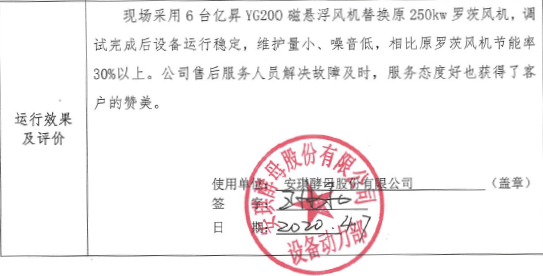

Raising fermentation level means there shall be a maglev blower with higher pressure and more flow to supply air. Through technical communication, ESURGING has developed maglev blowers with titanium alloy impeller, meeting Angel Yeast’s requirements on fermentation technique of higher pressure and more flow. Replacing 6 roots blowers of 250kW with 6 maglev blowers of 200kW has successfully broken the limitation of production capacity and profit caused by equipment limits.

Till now, Esurging has finished many reconstruction projects in Liuzhou of Guangxi province, Yichang of Hubei province, Chifeng of Inner Mongolia, Binzhou of Shandong province, Dehong of Yunnan province, etc. where Esurging maglev blower operate stably, save more than 30% of energy in average and has significant emission reduction performance. Now, Esurging, having replaced foreign suppliers, become the core supplier of Angel Yeast, which demonstrates high recognition and encouragement of ESURGING maglev blower technique from Angel Yeast.

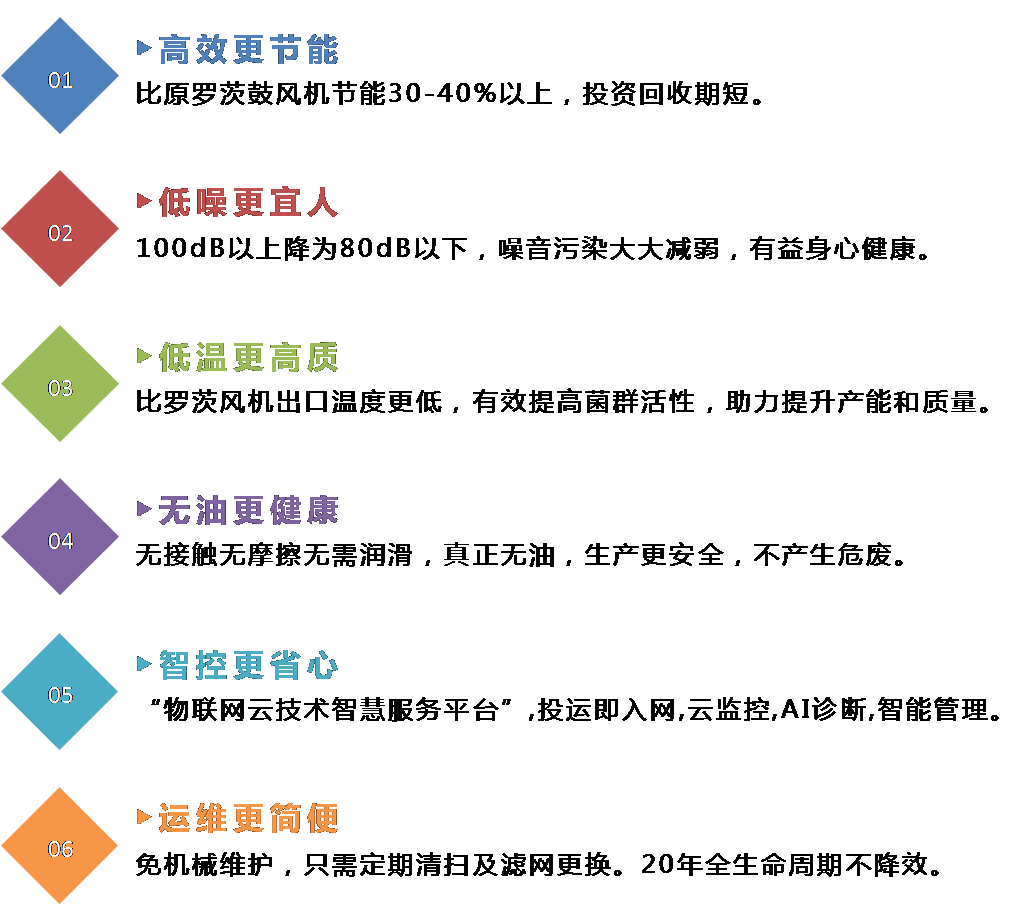

Advantages of Esurging Maglev Turbo Blower

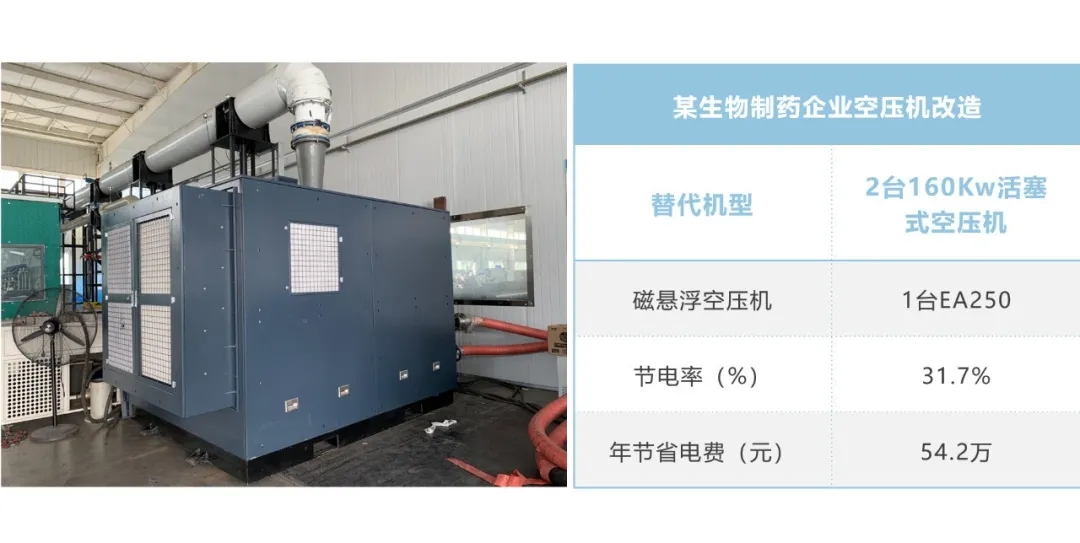

Energy-saving Maglev Turbo Air Compressor

Under the background where fermentation techniques and technologies are continuing to be optimized and upgraded, Esurging is committed to researching and exploring methods to provide more and better service for the customers. Thanks to the “maglev+” technology, the maglev air compressor for the food and pharmacy industry is launched this year to supply green, high-effective food grade compressed air for the customers.

In the future, Esurging, with maglev turbo blower, maglev turbo air compressor, maglev turbo vacuum pump and other products, will continue to improve its service to provide green solutions for air supply, vacuum and refrigeration for the industrial system.